6 Ways The International Supply Chain Is Evolving

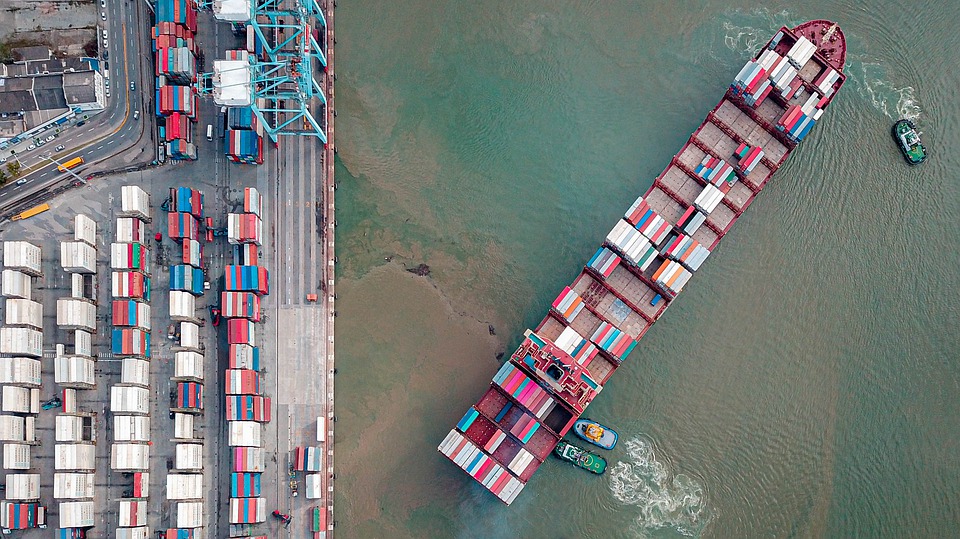

Supply chains around the world have been hit by a series of shocks in the past few months. First it was the virus, which positively stood the supply chains on their heads and shook the entire world. Customers wanted more products from small local businesses and that meant supply chains had to be made shorter, domesticated and focussed on higher-quality materials. Then the Suez Canal blockage by the massive 100,000 containers Evergreen, forced the world’s shipping channels to become blocked, jammed and for products on board to be wasted.

Then, there was a giant change in thought, regarding slow steaming. Ships were simply taking too long to get to port, putting them at risk in more unpredictable weather, shorter supply chains needing more speed and rising concern of access to the seas and oceans. There was and is, still a shortage of truck drivers. Here is how supply chains will evolve in the next few years.

What the driving force of the change is

The pandemic has been a massive wake up call for businesses, government, regulators, investors, etc. everyone knows this cannot be something that we just ignore. Supply chains have been stretched too thin, there have been too few producers and too many consumers. This is because, manufacturing is cheaper in poorer nations. So you have a gigantic workforce in places like India, China, Vietnam and Mexico, but they are all taking contracts from large brands that serve mainly Western or richer nations.

What does this mean? It means that, there are too few manufacturing options in the richer nations, leaving them to depend on far-away countries to bring in their goods. These voyages can be sometimes 10,000+ miles and take 25-60 days (freight shipping). As you can imagine, this takes ships too long to get loaded, set sail, wait their turn before docking and then being unloaded to then get back to the original loading port again. The maximum of 2 months to get to Europe from places like India and China is just absurd in this day and age. And here is why…

The age of slow steaming

Slow steaming is a technique that has been developed specifically by cargo shipping companies. It's very simple to understand but complex to implement. Ships that would normally cruise at 22knots, now usually sail the seas at 15knots. The manufacturers of ship engines have complained that they are stressing the engines by simply going too slow. The ship speed is slow enough to cause engines that rely on inertia problems. These are not steam engines that can happily remain at a slow and steady pace, these large turbine and electric diesel engines requires enough momentum of their own moving parts, to remain reliable and operate at safe zones of their performance parameters.

Slow steaming is intentionally, winding down the engines to go slow and to save on fuel. That is what the real issue with modern day shipping is. The need to save on fuel has meant that not only at supply chains thin and stretched, they are incredibly slow to deliver. Cargo shipping companies have been saving 15-20% on fuel by slow steaming, so the incentive to go slower is clearly there. However, no brand has the gaul to demand they get to their destinations quicker. They would increase the price of their shipping. Studies have shown, shipping one pair of $20 shoes from a place like Vietnam, costs just $0.25 when you ship in bulk. Imagine the profit margins! So forcing cargo ships to abandon slow steaming, would cut into these margins and who wants to do that!?

Climate change and homegrown talent

So okay, the shipping companies save a lot of money on fuel. So what? The amount of fuel used in supply chains reaching 10,000+ miles is still too much in today’s climate-conscious world. Consumers are demanding that less pollution and less wasteful strategies are employed by their governments. In a shocking turn of recent events, consumers openly say they are willing to pay more for goods that are ethically, sustainably sourced. They want more eco-friendly brands and brands to do more for the environment. How can governments sit back and still think, supply chains that are stretched to the limit, too slow, too costly to the world, still be something viable?

This is why big think tanks in the supply chain world such as Mckinsey are advocating brands and governments to rethink their approach. They say that climate could be the weak link in supply chains, and if just a little bit more pressure is put on brands by consumers, their world could change. There are mass protests around the world, concerning climate change, and if your brand is caught up in it, shown to be one of the bad guys, it could severely damage your business for many years. Perhaps, training the new generation, making manufacturing more affordable at home, is something to seriously consider investing in right now. Homegrown talent is more expensive in the beginning, but with proper modeling, tooling, training and investment, it could become much more affordable in a few years time.

The changing face of politics and commerce

Now we come to the elephant in the room. With regards to supply chains, politics is never too far. Political turmoil directly affects markets and supply chains, no one can deny this. As we have seen in recent times, there have been rising tensions in the South China Sea. countries such as Taiwan, China, India, the UK, US, Australia and New Zealand, all have a major part to play in the confusion. New tarrifs, export and import laws are being introduced almost monthly. This rapidly changing environment, hostile at times, is going to impact your business somehow.

This is why investing in supply chain solutions that can deal with packaging, labeling, returns and EDI is so important. You can speed up returns as things slow down in other parts of the world. You will have a higher chance of having the right kind of labeling, meeting regulations in several jurisdictions. And their electronic data interchange solutions help to keep information flowing across multiple systems to be accurate and consistent.

Who can say what will happen in the next decade regarding commerce in parts of the world such as China, Africa and Europe? For one thing, Western nations are hitting a low point regarding freight truckers.

A shortage of truckers

No matter how complex supply chains get, at the ground level there is always a need for a hard-working man or woman to do the work that keeps it all moving. In the recent months, we have seen a common and yet no less dramatic scene of food and supply shortages in Europe and in the US.

Food shelves were emptying faster than they were being restocked. It wasn’t because of political shocks to the system, it was simply a domestic and foreign shortage of truckers. You need skilled truckers who can drive very heavy and very expensive machines and cargo around countries, to actually deliver products to stores for them to then deliver to customers. This shortage of truckers led to shortages in food, thankfully not medicine, but it was a massive wake up call to the world because fuel shortages were very real. Vehicles piled into filling stations around the world, panic buying ensued and with good reason. Without fuel, people could not go to work. Despite the majority of people working from home, if you wanted to shop in person, visit family or go on a holiday using your car, this would no longer be viable.

So how could this be fixed? Better working conditions, higher pay, more competition between trucking companies and more favorable laws for trucking should do the trick. Once again, it showed that truckers are a vital source in the supply chain, and making sure trucking is a career that isn’t overseen lightly, is going to prevent something like this from happening again.

The lessons learned have a pattern

So what can be seen from these issues in the supply chain? Let’s break it down.

- Supply chains stretching 10,000+ miles are no longer viable or should not be seen as the only way to do things, anymore.

- Slow steaming is hard to combat, but shortening supply chains is a good start.

- Supply chains in countries that the West is butting heads with, will come under attack in the near future.

- Training people at home, shortens supply chains, increases quality and helps the environment.

- Supporting truckers and trucking companies is vital to the supply chain, something that should have not been overlooked.

We hope you enjoyed this exploration into modern supply chains and how they have been evolving. It should be an eye-opener to any business owner wanting to import or export. The key is to invest in talent locally, don’t rely so heavily on far away supply chains; maybe invest in some kind of hybrid system?

839GYLCCC1992

Leave a Reply