What You Need To Know About The Business Of Industrial Air Compressors

When you hear air compressors, a yesteryears industry must come to mind.

However, did you know that because of all the technological advancements now, air compressors can be used in residential areas, too? For those who don't know what an air compressor is, they convert electric power into potential energy.

This potential energy is then sealed into a pressurized air container. These compressors are also one of the main sources of function for most industrial appliances and basic homes.

So, if you're someone who is interested in the business of industrial air compressors, this is the right place to be. Let's find out more about industrial air compressors and how they will come in handy.

4 Types of Industrial Air Compressors

Now, whenever you're in the market looking for an industrial air compressor, you'll have to make sure that it caters to your needs. Conveniently, you can visit https://www.ablesales.com.au/air-compressors-factory-direct/ for a list of air compressors that will be well adjusted to your requirements.

There are currently four types of industrial air compressors available: single-phase, three-phase, petrol, and diesel. Let's find out more about these compressors and their features.

Single-Phase Air Compressors

The single-phase air compressor can work in any 220/240 standard power with a 3.0 horsepower motors. You can usually find these compressors in repair shops, home garages, automobile shops, and beauty salons.

Basically, you can find these compressors in any average small shop that uses air equipment. Made for people who work in smaller establishments, this is the best compressor that saves on energy bills and purchasing.

Lastly, the single-phase air compressors are more reasonably priced than the other types of compressors. If you're on a tight budget, this could be the compressor you can go with!

Three-Phase Air Compressors

The three-phase air compressor is mostly used in production factories, large-scale manufacturing, construction sites, and industrial facilities.

The 380/440 industrial power helps to additionally prolong the life of your electric motors. These types of compressors are great for heavy-duty air compression work, especially with equipment that draws the energy from it by using air.

Of course, for a heavy duty air compressor, the price will most definitely be high. It's a compressor with a high PSI and power that is crucial for large-scale factories.

Petrol Air Compressors

Petrol air compressors are favourable because they can be used in places without access to power grids.

By utilizing air, petrol air compressors can provide power to several pieces of equipment. This is a more sought out option than the other types because you can control the output and fuel usage.

If there is a need for a lower output, the compressor can easily be recalibrated to match the specifications. Not only are you saving your fuel for less amount of work, but it's also making less noise.

Many people will argue that diesel is more economical, but with fuel being cheaper and where you can control the usage and output, it's easy to tell which compressor is better.

The price for petrol air compressors are lower than diesel or electric compressors. It may only increase if there are any additional upgrades or features added to it.

Diesel Air Compressors

Diesel air compressors are best known for their highest form of output.

This is the only one that has the capacity to handle an expansive range of air equipment connections at the same time. They are also the only compressor that provides a higher torque than any other.

They can be super convenient thanks to them being portable and being able to work in areas where there is no stable electricity, such as tough weather conditions.

Diesel air compressors are pretty easy to maintain thanks to the way their ignition is designed.

The only drawbacks are that it makes a lot of noise compared to the other compressors and that it can't be used in indoors. The fumes that get released can pose health risks. Make sure you're wearing proper protective gear as you use it! We wouldn't want any accidents.

Wait, There's More?

That's right; there is indeed more to these four types of industrial air compressors. They are classified into four other kinds of compressors because of their mode of operation.

Rotary Screw Air Compressors

The rotary screw air compressors rely on two motors that provide continuous compressed air when gas is pressed into the chamber. With a horsepower that ranges from 30-200, this compressor can be classified as a positive displacement device.

Rotary air compressors have a short lifespan and need maintenance constantly. They also come as either a lubricated unit or completely oil-free. Research facilities and manufacturing industries mostly use this kind of air compressor.

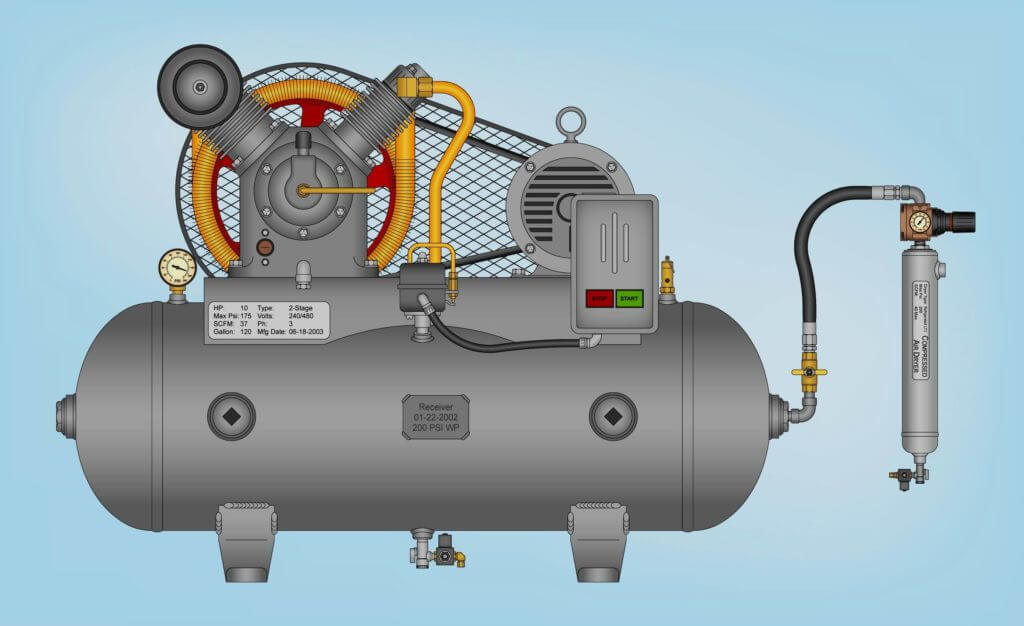

Piston Air Compressor

The piston air compressor stores and produces air at pressures that are somewhat higher than 100psi. They come in two forms – single and double cylinder compressors. The former can store air at 120-125psi, and the latter stores over 170psi.

They are also super easy to maintain and are reasonably priced as well. Mostly used in automotive industries, these compressors can be noisy when they are in use and need a large amount of oil for efficacy.

Scroll Air and Oil-free Air Compressors

The scroll air compressors are made of two spiral elements: one that is fixed and the other which rotates around to create enough suction. This then drags the air through a pipe that is kept stored in a compressed state.

They are perfect for air conditioners and refrigerators because they come with casings that help to minimize heat and noise.

The oil-free compressor, as the name suggests, doesn't use oil to perform operations. You'll find these compressors normally at hospitals or in facilities that have sterile environment. The non-oil usage really helps with keeping things sterile.

Final Thoughts

In conclusion, we hope the information we provided actually does help you to know more about industrial air compressors. The various types and their features will help you decide which one you want to go for.

Always make sure you've done your research about the features, functions, cost, and other uses that the compressor will bring in. Go out there and make the most of your business!

839GYLCCC1992

Leave a Reply