4 Tips to Make your Equipment Last Longer

Every business needs equipment. If you work in an office, it might be computers, printers and external hard drives. And if you operate a warehouse, it could be forklifts, cherry pickers, and pallet trucks. Whatever tools and machinery you require, they are generally extremely expensive. Your equipment makes up a huge portion of your business budget, and therefore you want it to last a long time.

But technology is not perfect, and you will certainly experience malfunctions and breakdowns from time to time. Some of them you will be able to fix yourself, whereas others will require a professional repair job or even a complete replacement. When this happens, it not only takes up a chunk of your budget but can be incredibly disruptive to operations while you wait for the equipment to get up and running again.

To help you save money and protect your business, there are steps you can take to extend the lifespan of your equipment. With proper training and maintenance, you can get more out of each piece of technology and spend less time worrying about it going wrong. Here are a few tips to get you started.

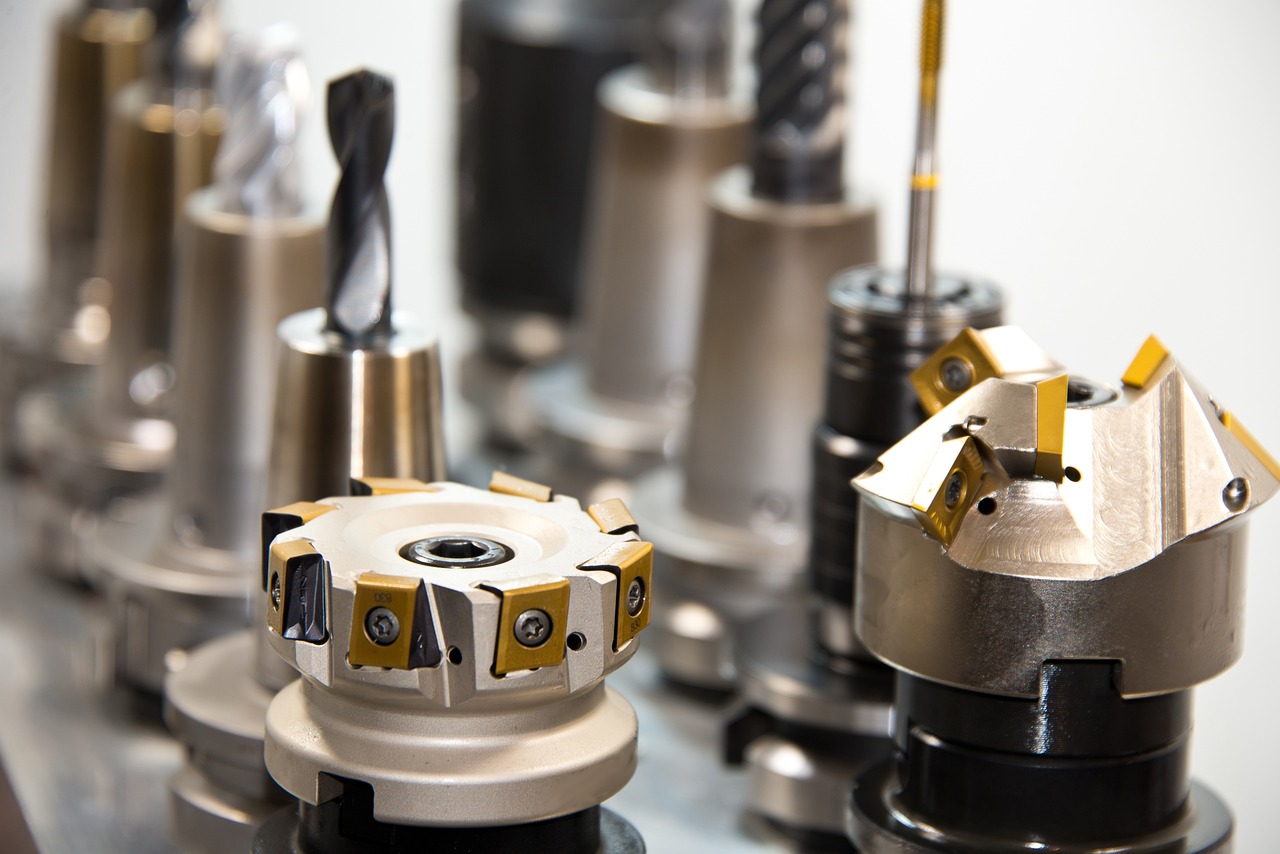

Buy quality items

Every business owner wants to save money, but your frugality can still come at a cost. It is always better to spend more on a quality piece of equipment than to save money on a cheaper but less effective one. Do your research and browse different suppliers. For example, if you need to buy some new precision bearings for your warehouse equipment, you should shop around and find the best options for the best price. Lily-Bearing, a bearing manufacturer, offers great options at affordable prices. You may end up spending a little more initially but you'll save money in the long run by avoiding breakdowns and costly replacements.

Train your staff

Many equipment malfunctions occur due to human error. If your staff use the tools incorrectly, they risk damaging them and causing workplace incidents. Make sure every single member of the team undergoes rigorous training before being allowed to use any machinery or hardware. This will ensure they produce the best results and minimize any possible disruption. It will also teach them to identify any issues so they can be fixed before they create a problem.

Service regularly

Equipment shouldn't only be maintained when it goes wrong. It should be regularly serviced to ensure it is always in peak condition and to identify any warning signs or wear and tear. The frequency of the service will depend on the particular equipment in question but it should follow a regular schedule.

Store it correctly

The way in which you store your equipment can make a huge difference to its lifespan. If items are left exposed to the elements, or in damp and dusty conditions, they will wear out a lot quicker than they should. Make sure they are stored as per the manufacturer's instructions, and looked after even when not in use.

By following these tips you will maximize the lifespan of your business equipment and save yourself a whole lot of money in the long run.

839GYLCCC1992

Leave a Reply