Comparing Carbon Fiber To Steel: Which Is Best?

While many manufacturing businesses focus on a better waste process to protect the planet and conform to the newly increased demand for cleaner air, it remains vital to prioritize essential changes within your business.

And as the ambitious owner of a manufacturing business, there's no doubt that you already have your attention spread thin over various critical areas of business. Not only do you need to prioritize reducing waste, but you also have to find ways to increase product quality, keep cash flow ideal, boost profit margins, and enhance sales. And all this with the primary goal of reducing costs and bettering your bottom line.

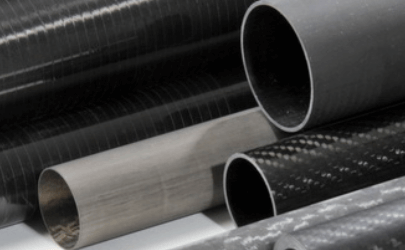

And if your manufacturing business is using tubing for various reasons, you might be wondering if carbon fiber tubing is better than standard steel tubing options. So, if you're thinking of finding a supplier for longer-length carbon fiber tubes or any other specific carbon fiber tubing, and you aren't too sure if the change has any benefits for your business, we've compared the two options to help you make the most informed decision.

Carbon Fiber Explained

Carbon fiber is a material created from carbon and has a pretty high tensile strength due to its crystalline structure. For this specific reason, it can be used to fabricate high-strength, and lightweight composite parts with fiber merged inside the polymer matrix.

The physics behind carbon fiber renders it an exceptionally rigid and strong material. It also has a notably high resistance to deformation according to the measurements of the material of durability. What's more, the tensile strength of carbon fiber is one of the highest and most impressive of all other material alternatives. Therefore, carbon fiber is an excellent choice for manufacturers.

This material can be used in robotics, metrology, automotive, wind turbines, industrial machinery, and various other things. As a result of the vast range of uses for carbon fiber tubing, it's fast becoming the ideal choice for manufacturers of all sizes.

The main downfall of carbon fiber is the cost, as it is notably more pricey than steel. And this is mainly due to the timely process behind creating the material. Unlike steel, carbon fiber goes through a series of procedures to become carbon fiber. And for this reason, it's also unlikely that the prices of this strong material will ever genuinely decrease to a significantly pocket-friendly price range.

But even so, the cost of carbon fiber is still suitable for manufacturers who need to use the material. Opting for steel to save expenses is not a logical decision, as steel is not nearly as durable and has far less practical uses for manufacturers. So, suppose you need to use carbon fiber. In that case, it is not a viable decision to switch to a cheaper material as you won't achieve the same or even similar results with many other carbon fiber alternatives in most cases.

Steel Explained

Steel has been the go-to material of choice for several decades already. And this is primarily due to the high elasticity of the material. Steel is also readily available, which makes it a pretty affordable choice. However, the main downfall of steel is that the heavy density can wear down machines reasonably fast.

The weight of steel also slims down the relevant uses significantly. As a result, carbon fiber serves more functions in comparison to steel. Regardless, steel is still an essential material for various manufacturers, as carbon fiber is not always suitable.

Steel is best for high tensile strength products that should be low cost. As a result, steel is often used in construction for buildings, tool production, ships, trains, automotive parts, electrical appliances, and various types of weapons.

The Bottom Line

While steel might be the longer trusted option, it is a heavier and more dense material that is somewhat more challenging to use compared to carbon fiber. Even though steel is readily available and more affordable, it often does not last as long as carbon fiber.

What's more, carbon fiber has various applications, as it can be used to create multiple types of products. So, if your manufacturing business is making goods that should be lightweight yet rigid, it is the ideal choice of material. That said, carbon fiber is also suitable for various heavy machinery parts, so even if your business makes other products, you can still benefit from using carbon fiber.

Carbon fiber is the best choice for specific uses, as the more durable and robust option than steel. So, if you are thinking about switching to carbon fiber, it is best to find a supplier that produces high-quality carbon fiber products at affordable prices.

839GYLCCC1992

Leave a Reply