4 Benefits Of Conduit Sealing For Electrical Utility Systems

Even pioneer scientists like Benjamin Franklin and Thomas Edison would probably not believe how reliant we have become on electricity. It has become a must-have essential, powering almost every aspect of our lives, from our homes to commercial workplaces, hospitals, industries, and transport.

In fact, for most of us, the worry is rarely whether we can get electricity or not but how we can ensure we have power at all times. And we just might have an answer for you. One major way to reduce power downtimes is maintaining the integrity of the wiring infrastructure, which you can achieve by including one simple but powerful step—conduit sealing.

In this article, we will explore not only the concept but also the key benefits of conduit sealing.

Understanding conduit sealing

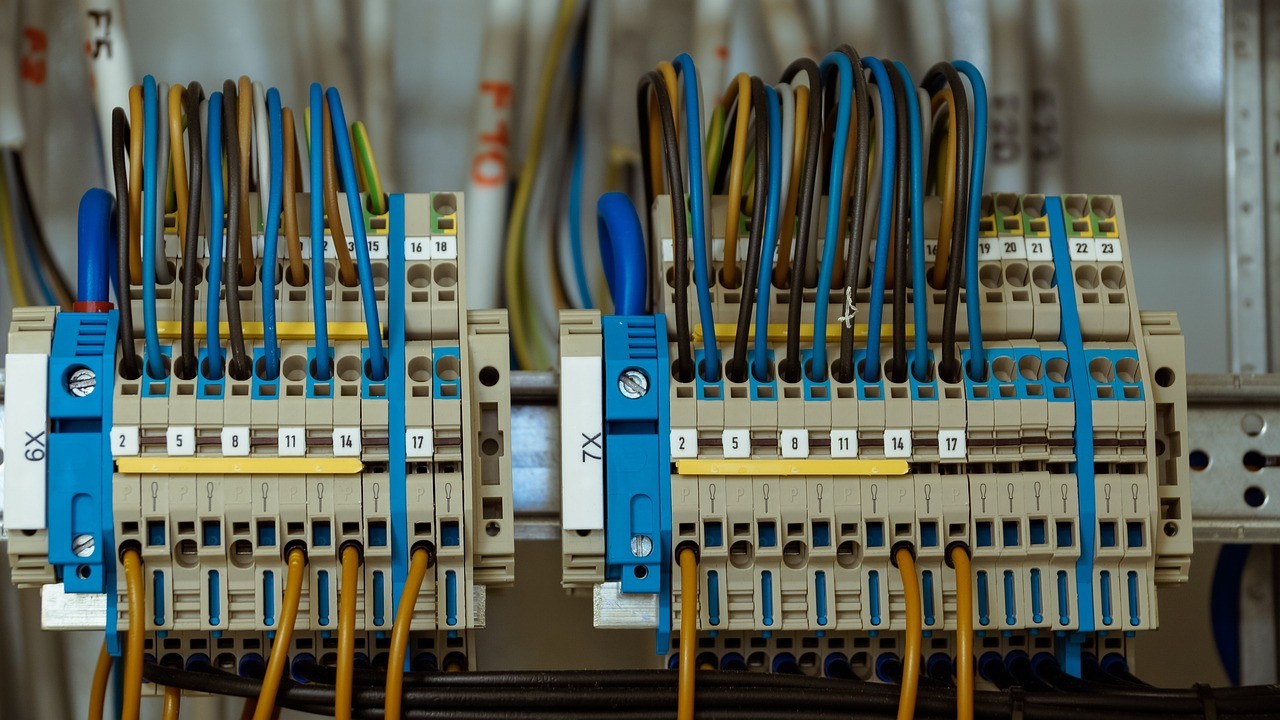

Conduit sealing is the process of creating a secure, airtight, and waterproof seal at the points where electrical conduit systems enter or exit buildings, equipment, or enclosures.

Conduits are the protective tubes or pipes that house electrical wires and cables. They are designed to protect the wiring from outdoor elements such as moisture, dust, and pests. Therefore, by sealing the conduits, you ensure that these unwanted elements do not enter and cause potential damage or disruption to the electrical system.

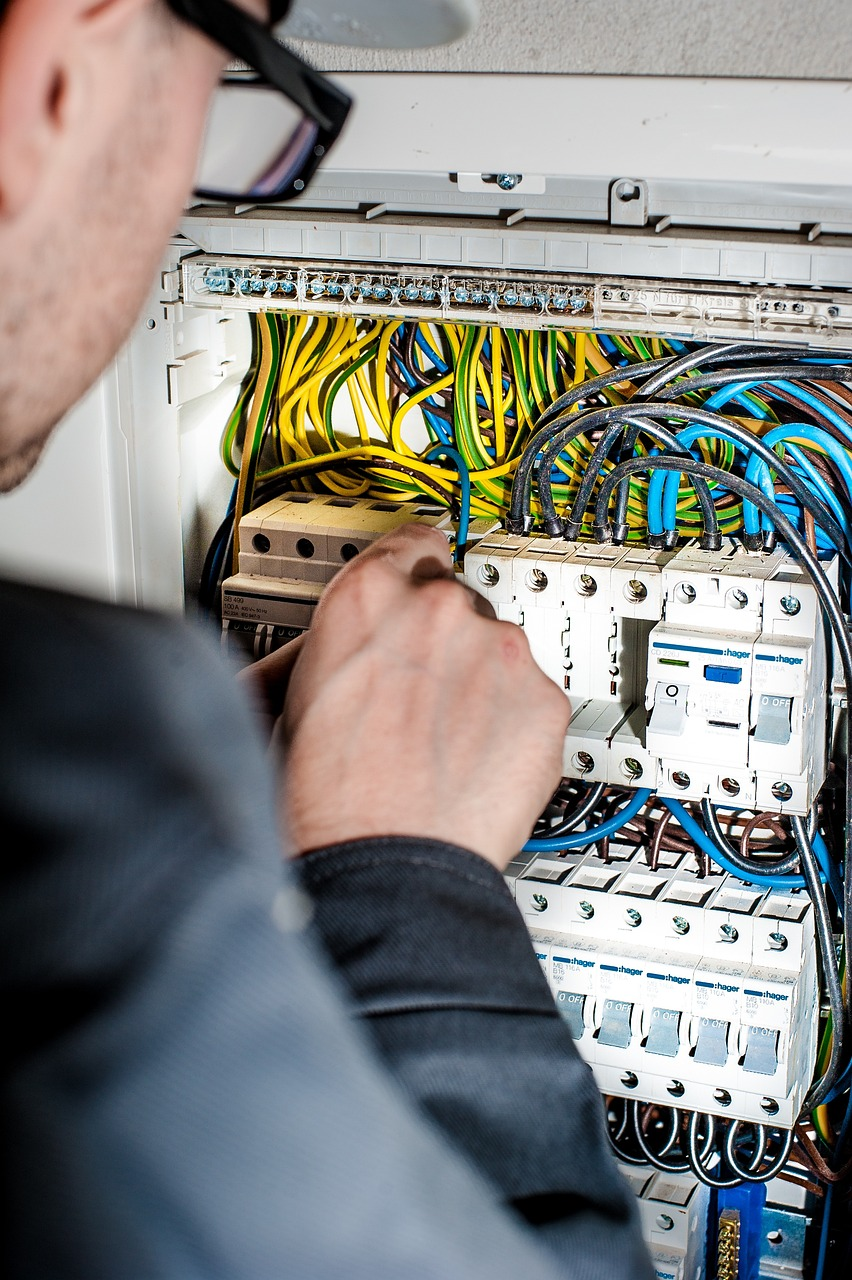

So, how is conduit sealing done? Here's a brief process:

- Preparation: Clean the area around the conduit to remove any dirt, debris, or moisture. A dry surface without any contaminants will help the sealant bond properly.

- Choosing the right sealant: Your choice of sealant will depend on the environmental conditions, the type of conduit, conduit sizes, and the level of protection needed. Some key types of sealants include rubber gaskets, silicone, foam, conduit sealing bushings, or epoxy and polyurethane for more industrial settings.

- Application: Apply the sealing material around the conduit where it meets the wall, floor, or enclosure. Ensure you follow the manufacturer's instructions for application to ensure optimal performance. Keep in mind liquid or compound-based sealants, such as silicone or epoxy, will require time to cure and harden.

After the sealant is applied, it's important to check for any gaps or areas where the seal might not be fully effective. In some cases, you might need additional layers of sealant to ensure you create a tight and secure seal.

Advantages of sealing conduits in electrical utility systems

Conduit sealing in electrical utility systems has a variety of crucial benefits that help protect both the infrastructure and the system's performance. Let's dive into four of the key benefits of conduit sealing.

1. Helps prevent moisture

Moisture is one of the most damaging elements that can compromise the functionality of electrical utility systems. Whether it's from high humidity, rain, or even flooding, when moisture enters a conduit, it can wreak havoc on the internal wiring and components.

Some of the issues water damage can cause include:

- Corrosion: When metal wires and connectors are exposed to water, they begin to corrode, weakening the connections and increasing the risk of electrical failure. Over time, this corrosion can lead to complete system breakdowns or require costly repairs.

- Short circuits: The other serious problem caused by moisture is short circuits. Water is a conductor of electricity, and when it makes contact with electrical wires, it can create unintended pathways for electricity to travel. This can lead to shorts, which may cause power outages, sparks, or even fires.

By sealing conduits, you create an airtight and waterproof barrier that prevents moisture from entering and affecting the electrical components. The seal acts as a protective layer, effectively blocking water from entering. It ensures that your wires and cables remain dry and in good condition.

This extends the lifespan of your electrical components and also helps maintain the overall safety of your electrical systems. In addition, sealing conduits minimizes the need for frequent maintenance or replacement of damaged components, which will save you both time and money.

2. Minimizes the risk of electrical fires

Electrical fires are a serious concern in any electrical system and are caused by various factors, such as faulty wiring, overloaded circuits, or even environmental hazards like moisture. These factors disrupt the electrical flow, potentially sparking a fire. Conduit sealing minimizes these risks by ensuring a clean and controlled environment for your electrical systems.

The sealing materials used, such as silicone or foam, effectively block out dust, debris, and other potential contaminants. This means that the chances of these elements coming into contact with your wiring are significantly reduced. As a result, the risk of electrical fires is minimized.

In areas where fire safety is a primary concern, like industrial buildings or high-rise apartments, use specialized firestop sealants and materials. These sealants expand when exposed to heat, sealing any gaps around the conduit to prevent the spread of flames and smoke. This forms an even tighter seal that helps contain fires.

3. Protection against pests

Pests like rodents, insects, and other small creatures might not be the first thing that comes to mind when thinking about electrical systems, but they can cause significant damage to the wiring and components inside conduits.

Rodents, such as mice and rats, are particularly notorious for chewing on wires, which can lead to short circuits, system failures, and even fire hazards. Insects, on the other hand, might build nests inside the conduits, causing insulation damage.

By sealing the conduit tightly, you prevent pests from gaining access to the wiring, which helps maintain the integrity of the system.

In addition, sealing conduits can save you money on repairs and maintenance. Pest-related damage is often costly to fix, especially if the issue goes unnoticed for a long time. So, by addressing the problem upfront with proper sealing, you lower the number of times you have to repair or replace damaged components. Oh, you also won't need to pay for extermination services, which can be both time-consuming and expensive.

4. Dust protection

When dust and other fine particles enter electrical conduits, they can accumulate on wires, connectors, and other components inside, leading to several potential issues.

One of the most concerning is the risk of overheating. Dust can act as an insulating layer that traps heat around electrical components, preventing proper heat dissipation. Over time, this can cause the system to overheat, damaging wires and potentially leading to system failures or fires.

Sealing conduits helps prevent dust from entering your electrical system, keeping the internal components clean. This is especially important in environments where dust levels are high, such as factories, warehouses, or areas near construction sites.

Dust buildup inside conduits can also attract pests, further complicating the situation. Therefore, by sealing conduits and preventing dust from getting in, you reduce the likelihood of pest-related issues that we discussed earlier.

Conclusion

As we've seen above, there are many benefits of conduit sealing for electrical utility systems. It prevents moisture, minimizes fire risks, blocks pests, and keeps out dust, which helps enhance the safety, efficiency, and longevity of your system.

Whether it's for a large-scale industrial facility or a residential property, making this simple yet impactful improvement will for sure save you time, money, and stress in the long run.

839GYLCCC1992

Leave a Reply