The Anatomy of Bicycle Wheels: Around and Around We Go!

Table of Contents

Wheels are composed of three basic parts: the rim, the spokes, and the hub. The material type, quality, and design of these parts will influence how well your wheels perform.

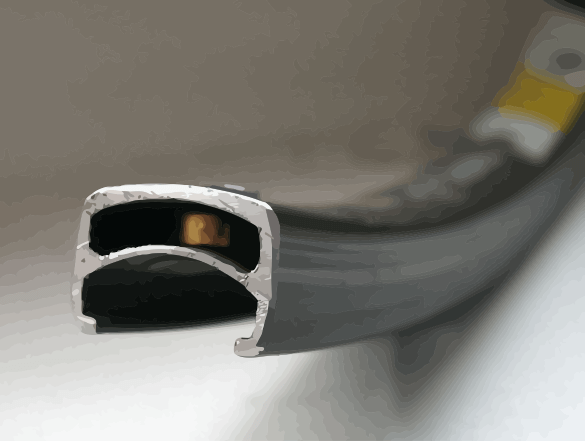

Rim Cross Section

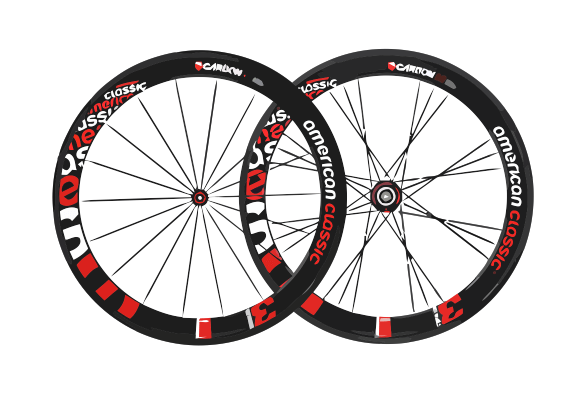

Rim Cross Section Deep Dish Wheel Rims

Deep Dish Wheel RimsRims

The rim is the outside part of the wheel that the tire sits on and the spokes attach to. Rims can be made of various materials. From heaviest and least expensive to lightest and most expensive they are: steel with chrome plating to prevent rust, aluminum alloys, or carbon fibre (special brake pads are needed with carbon fibre rims). The ideal rim is strong where it's needed yet flexible to provide a comfortable ride; light to improve speed; aerodynamic if you race; reliable; durable; and resistant to rust. Rims must also be able to hold the tire on securely and provide a braking surface for brake pads (unless disc brakes are used).

Although there are different variations, to the right is what the average rim looks like if you were to cut a cross section. The official term given to this type of rim is ‘clincher.' Rim tape is needed, pending on the rim type to prevent the tube from being punctured by the spoke end. Truing is the term given to straightening a warped rim, and it is done by adjusting the spoke tension.

And just below the cross-section, is an example of a ‘deep dish' rim. The main advantage is aerodynamics, however, this will be reduced if there is a cross wind. Some riders consider them stronger than shallow rim. Be aware that longer valve tubes, or valve extenders are needed. In addition, the spokes will be shorter, something to keep in mind if you need to replace them.

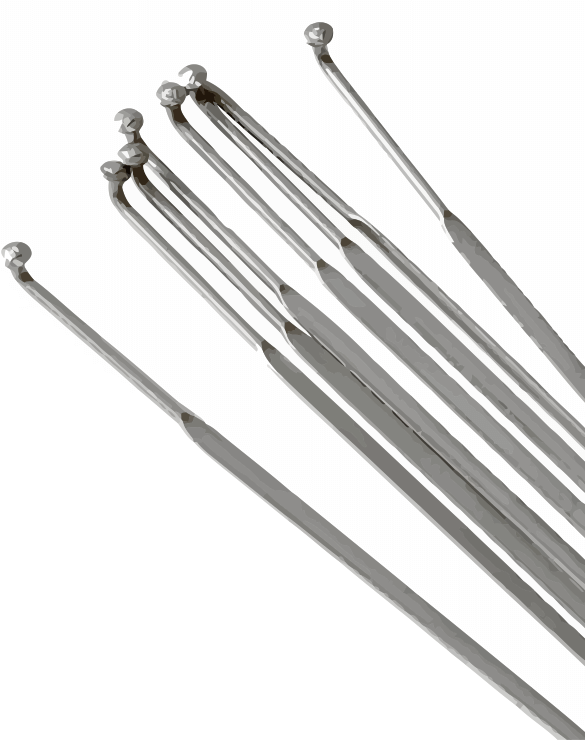

Butted and Bladed Spokes

Butted and Bladed Spokes Spoke Lacing Crossing

Spoke Lacing Crossing Spoke Nipples

Spoke NipplesSpokes and Nipples

These are metal wires that connect the hub onto the rim. They can be made of various material such as stainless steel, aluminum, titanium, or carbon fibre. They can also be of different designs, known as buttness, as explained below. They must always be under a specific tension in order to maintain the proper wheel shape, both laterally and radially. The tension is controlled at the nipple, the part that attaches the spoke onto the rim. Warning: if the tension is too high the nipples will permanently damage the rim.

Buttness

The traditional spoke has the same thickness from one end to the other, and these are perfectly fine for most riders. I suppose the term for these would be non-butted.

Single butted spokes are thicker only near the hub.

Double butted spokes, which are thinner in the centre section, are lighter, have increased aerodynamics as they slice through the air, and are more elastic.

There is also a triple butted spoke, which is thickest at the hub, thinner at the nipple, and even thinner in the middle.

Spokes can also be bladed, which assists with aerodynamics, unless of course there is a cross wind.

Spokes are usually laced in a fashion so they cross each other near the hub, which provides strength. The cross can be quadruple, triple, double, or even non-existent. The more crosses, the stronger. However, more crosses means the spokes will be longer which will increase the wheel weight. Usually you can get away with no cross on front wheels, but not on rear wheels.

The number of spokes on a wheel can vary, with a traditional wheel having 36 spokes. Some modern wheels can have as few as 20 spokes. Although a lower number of spokes will make the wheel lighter, it's typically at the cost of strength and durability.

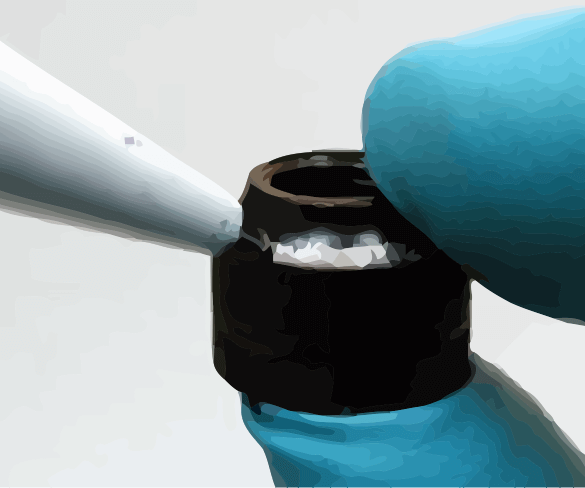

Nipples are the parts that connect the spoke onto the rim. They are the part that will control spoke tension and require a spoke tool to be tightened/loosened. Nipples can be made of aluminum alloy or from brass. Aluminum ones are lighter, but less durable. Brass is heavier, but more durable.

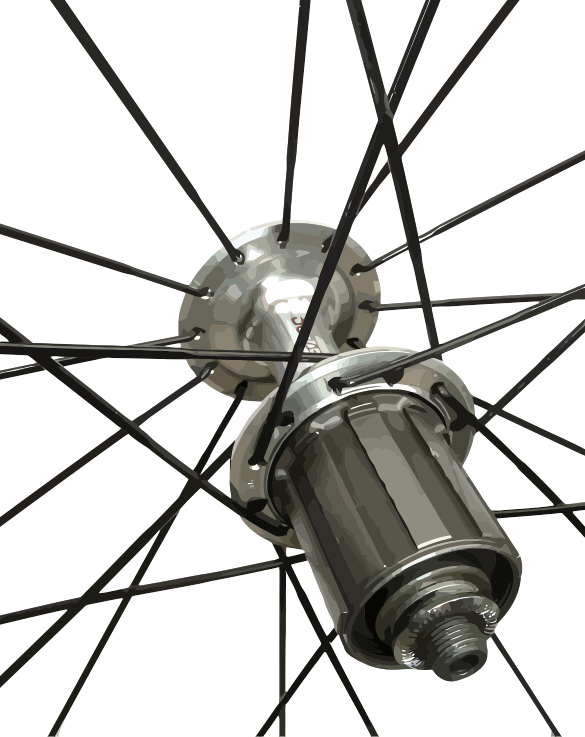

Rear Hub

Rear HubHubs

Hubs attach to the fork or the frame and hold the spokes. It consists of an axle, bearings, and the flange. A good quality hub, besides being lighter, will have good internal components such as high-quality bearings that reduce friction. The rear hub must also be able to hold the rear drivetrain.

The axle is usually a quick release, allowing quick removal of the wheel. Some bikes, such as single-gear or stunt bikes, have a bolt, which makes them more secure. There are different sizes of axles so make note of yours if you're considering replacing them.

Checking for Bearing Wear

Checking for Bearing WearBearings are little round balls that sit between two attached pieces of metal to move freely. They can be made of steel or ceramic. Some systems are serviceable, meaning the bearings can be removed and cleaned, while others have a cartridge which is simply replaced. On replaceable bearing systems there will also be cups and cones which hold the bearings in place. Any time you take these parts apart you should check for wear and damage. The biggest enemies of bearings are over tightening and dirt. Proper greasing is vital to avoiding to maintaining the integrity of the bearing. Unfortunately, even the smallest worn out area on a cup or cone means it should be replaced or it will damage other parts and affect your ride. You can check for cup or cone wear visually, or better yet, gently roll a ball point pen over the surface to feel for any rough spots.

The flange is the part of the hub that has the holes for the spokes. The number of holes on the flange and the number of spoke holes in the rim must be the same, if you ever replace either one. If the spokes are too tight, or from metal fatigue, sometimes flanges can break.

Rotational Mass

When it comes to bicycle weight, the wheels are probably the most important factor to consider. If you are interested in making things lighter, replacing the wheels, along with the tires, should be your first step. The main reason for this is due to rotational mass. You see, because the wheels rotate, their weight increases exponentially as speed increases. Whereas the frame weight will never change regardless of the speed.

Let's investigate this further using some simple math. When you're travelling at 0 km/h the wheel weight will remain the same, let's say 1 kg. Then, you increase your speed to 5 km/h, because of rotational mass, your wheel weighs 2 kg. When you increase your speed to 10km/h you'd expect your wheel to weigh 4kg because you doubled your speed. However, the increase is non-linear. This means your wheel will now weigh 4.5kg. So, the faster you go the more the rotational weight. Understand that these numbers are just made up, I'm using them just to make a point. It would be almost impossible to calculate the exact rotational mass, as there are many factors that come into play. For example, wind speed and direction, are you riding on a flat surface or climbing.

A couple of other things to keep in mind::

- The larger the diameter of the wheel, the more rotational mass it will have.

- The more mass that is farther away from the centre will also mean more rotational mass. This means that a heavy hub will have less of an effect than a heavy tire.

- A lighter tire and tube may be a good way to easily reduce rotational mass.

- Since climbing is at slower speeds, rotational mass will be less. However, weight is more noticeable while climbing.

- While going down a hill, because of higher speeds, rotational mass will be higher. However, higher mass going down a hill means higher acceleration.

Leave a Reply